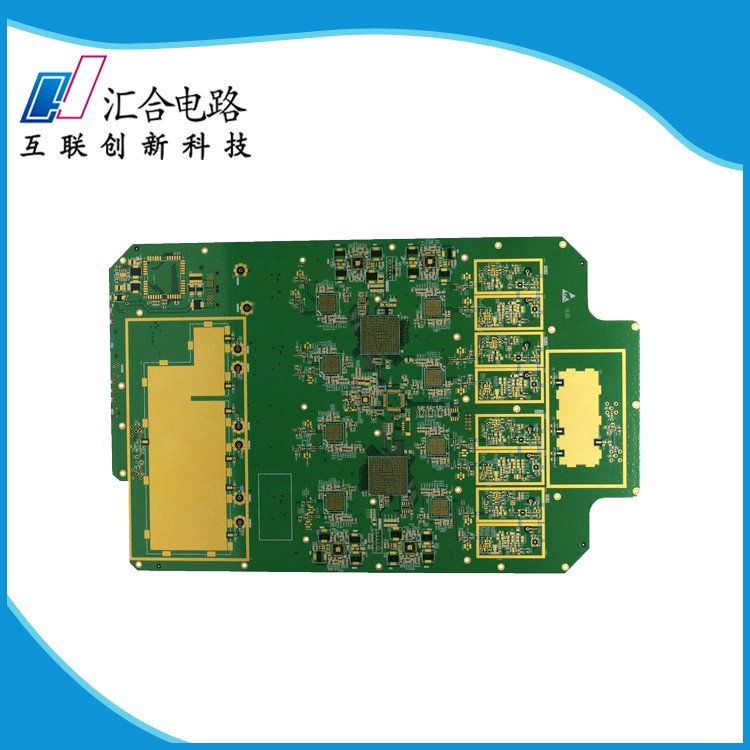

今天,我想谈谈pcb快速打样印刷电路板制造中的一个关键部分——表面光洁度。表面处理在要安装的部件和互连电路之间形成一个关键的接口。

作为一个提醒,本博客的重点之一是研究pcb快速打样制造业所涉及的技术。As its most essential function, the final finish process is intended to provide exposed copper circuitry with a protective coating in order to preserve solderability. In a more expanded view, the final finish coating is required to meet dozens of functional criteria, including solderability, environmental, electrical, physical, and durability demands. The past decades have brought about a wholesale transformation in this segment of the industry - a wide variety of functional, environmental, engineering, cost, productivity, and failure mode issues have contributed to this frequent change.

作为其最基本的功能,最终的精加工工艺旨在提供暴露的铜电路,具有保护性涂层,以保持可焊性。

在一个更扩展的视图中,pcb快速打样最终的涂层需要满足几十个功能标准,包括可焊性、环境、电气、物理和耐久性要求。过去几十年来,在这一行业中发生了一次大规模的变革——各种各样的功能、环境、工程、成本、生产率和失效模式问题都促成了这种频繁的变化。

Nonetheless, years of manufacturing experience and constant innovation has enabled PCB International to be a leading edge provider for all your surface finish needs. Including, but not limited to: HASL, ENIG (Immersion Gold), Organic solderability preservative (OSP), immersion silver, immersion tin, Electrolytic nickel/electrolytic gold, electroless gold, etc. Below lists the pros and cons of a number of the more popular surface finishes - most relevant in today’s applications. Please note that all of these are available at PCB International!

然而,多年的制造经验和不断创新,使pcb快速打样成为领先的供应商,为您所有的表面光洁度的需要。包括但不限于:HASL、EnIG(浸金)、有机可焊性防腐剂(OSP)、浸银、浸入锡、电解镍/电解金、化学镀金等。下面列出了一些比较流行的表面处理的优点和缺点-在ToDA中最相关的。Y的应用。请注意,所有这些都可以在PCB国际!

相关阅读:Pcb快速打样HDI基板【汇合】